“In 2050 technologies and procedures available allow a 75% reduction in CO2 emissions per passenger kilometre to support the ATAG target and a 90% reduction in NOx emissions. The perceived noise emission of flying aircraft is reduced by 65%.”. This is what is stated in the EU’s vision for aviation Flightpath 2050[1]. To achieve this goal, the aviation sector is developing many new technologies across its whole value chain. Along with SAF and hydrogen propulsion, focus is being put in the development of fully electric aircraft. However, such technology poses major technical challenges due to the energy to weight and power to weight ratio of current battery technology. Hence, Hybrid Electric Propulsion System (HEPS) poses itself as a promising solution.

What is hybrid propulsion?

Hybrid electric propulsion, in the most general sense, combines an electric motor with an Internal Combustion Engine (ICE), or in more general sense a second power source, in a similar fashion to what is seen in current hybrid electric cars. In almost all designs the electric motor drives a propeller (the propulsor). For this reason, HEPS is being developed for either General Aviation (GA) aircraft or regional turboprops. The Internal Combustion Engine could also be substituted by a gas generator, or even by fuel cells [2]. The electrical energy to the motor can be provided either by a battery pack, or from an electrical generator. The latter converts the energy coming from the second power source into electrical energy.

When it comes to the powertrain design, three major architectures have emerged:

- Series HEPS architecture,

- Parallel HEPS architecture, and

- Series-parallel HEPS architecture.

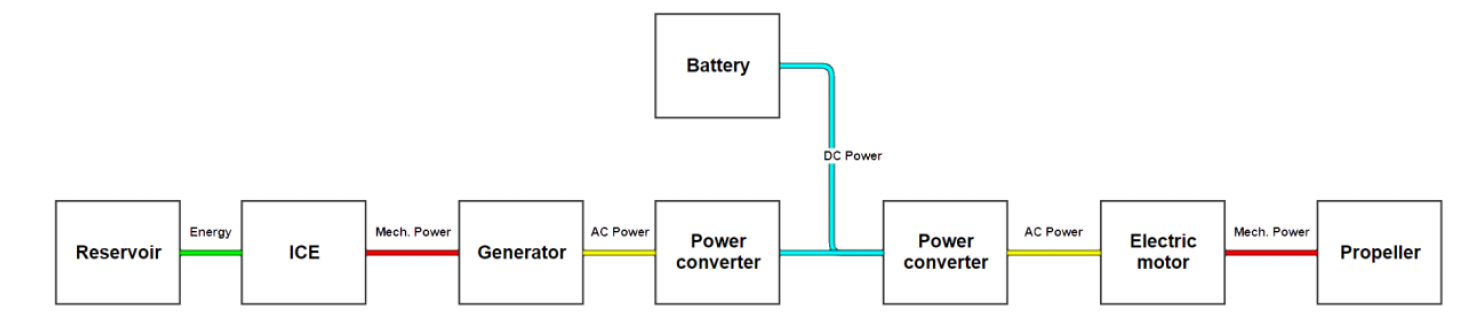

In the series configuration, the propeller is only driven by the electric motor. The (electrical) power to drive the motor is provided either by the battery and/or an electric generator coupled to the ICE.

Schematics of a series HEPS architecture (source: [2])

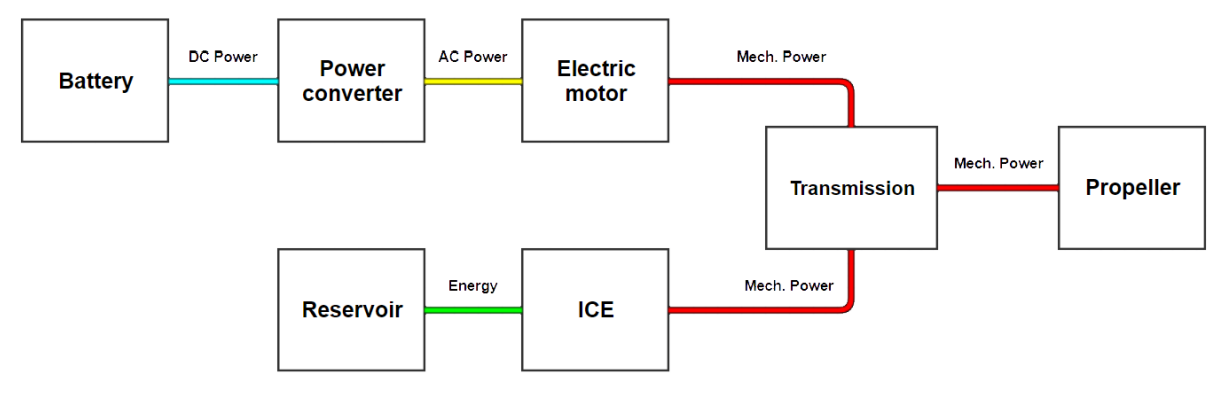

In the parallel architecture, mechanical power is provided both by an electric motor, powered by batteries, and by the ICE. The transmission couples both input mechanical power sources into a single output shaft to the propeller.

Schematics of a parallel HEPS architecture (source: [2])

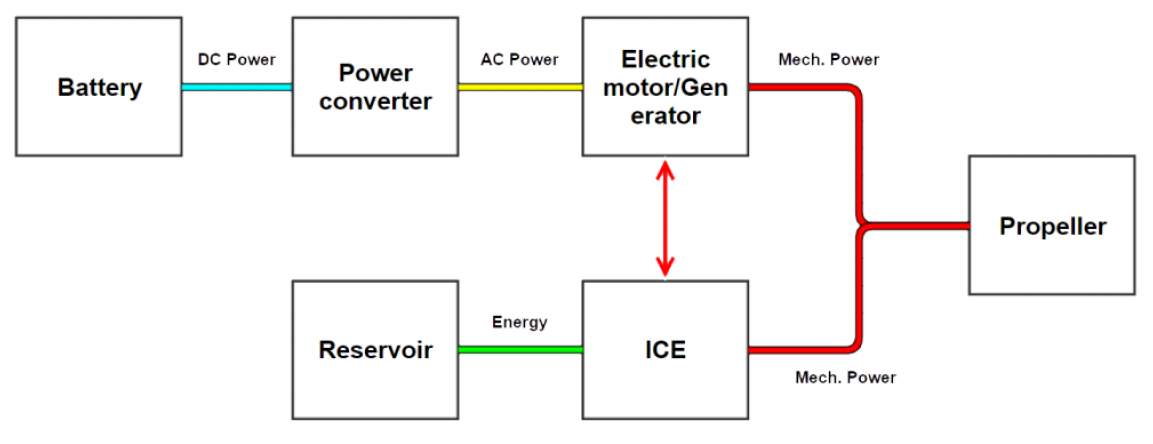

The series-parallel architecture, as the name suggests, combines the series architecture with the parallel one, and many different specific configurations have been developed. Although such configuration can be regarded as being the most advanced hybrid architecture, giving great flexibility in the design, it is also the most complex and heavy of the three.

Schematics of a possible configuration for series-parallel HEPS architecture (source: [2])

Benefits and drawbacks of hybrid electric propulsion

Hybrid electric propulsion shows promising advantages. In the series architecture, if the batteries have enough energy and power density, the aircraft could operate in fully electric mode. With current and projected battery technology, this could be achieved during the less power intensive phases of flight, such as descend and landing. For the latter, however, the full power needs in case of a take-off or go-around need to be carefully examined during the design of the powerplant. Furthermore, electrical energy is produced during the flight and can be stored in the batteries, allowing for an extended range and/or for fully electric operations for the final stages of the flight. Finally, from a safety perspective, having two separate power sources provides redundancy in the powertrain system, increasing the safety of such configuration.

Moreover, the series architecture is relatively simple: the propeller is only driven by one power source (the electric motor), hence eliminating the need of having complex and heavy gearboxes. Furthermore, the ICE can run at constant, optimal RPM, increasing its efficiency and hence requiring lower fuel burn. However, energy will be lost in the conversion phases (from mechanical to electrical, and from electrical to mechanical), even though electric generators and motors efficiency are quite high (in the order of around 90%) [3]. The need of a generator, which adds weight to the powertrain, is one of the major drawbacks of such design.

For the parallel architecture, the main advantage is that there is no need for an electrical generator; furthermore, the electric motor can be smaller, and hence lighter. However, such weight advantages are counteracted by the added complexity and associated mass of the gearbox, which has to combine two mechanical power inputs (electric motor and ICE) into one output shaft to the propeller.

A drawback that is common for all the HEPS design is that there is still the need for conventional fuel to power the aircraft, even if fuel consumption is lower compared to traditional aircraft. However, as for conventional aircraft, SAF could be used for HEPS powertrains as well.

The benefit of the potential reduction of the noise imprint of the aircraft deserves and article by itself, given the complexity of the topic. Research work is being done in this field. [4] focusses on the noise analysis for GA hybrid electric aircraft and concludes that a reduction of approximately 3 dB could be achieved when flying fully electric in the departure and climb phases of an airport traffic circuit. On the other hand, [5] compares the noise impact of a traditional ATR42 against a modified, hybrid version, concluding that the hybrid configuration could have a higher noise impact on the ground, both in terms of LAE and LDEN. Hence, definitive noise evaluations on hybrid electric propulsion cannot yet be drawn.

Overview of the current HEPS aircraft

In recent years, many aircraft testbeds have been developed to investigate hybrid electric propulsion.

Starting with General Aviation, a consortium comprised of Siemens, EADS and Diamond Aircraft developed in 2011 the Diamond DA36 E-Star (and later in 2013 version 2) as one of the first hybrid electric aircraft suitable for commercial use. The aircraft features a series architecture, where the propeller is run by a 70 kW (94 hp) electric motor and electrical energy is provided by 30 kW (40 hp) reciprocating engine, coupled with a generator and battery packs. The company claims that this aircraft achieves a 25% reduction in fuel consumption and a drastic reduction in noise emissions during take-off [6]. Moreover, in 2018, the company announced the first flight of the world’s first multi-engine hybrid electric aircraft, based on the DA40 aircraft [7].

Within the EU funded HYPSTAIR (Hybrid Propulsion System for General Aviation Airplanes) project, a 200 kW serial HEPS has been developed and ground tested.

American based Ampaire is developing and testing different GA concepts. An hybrid electric retrofit of a Cessna 337 Skymaster is mainly being used as a tesbed aircraft for components, according to the company’s website. The manufacturer is also developing a modified Cessna 208B Grand Caravan, claiming that its emissions are the lowest in its class, with fuel savings between 50% and 70% [9].

Demonstrators for regional propeller aircraft are also being developed. United Technologies (now part of Raytheon Technologies) is developing a hybrid electric testbed based on the Dash 8-100 twin turboprop. The aircraft is equipped with a parallel hybrid configuration on one of the two engines, with a 1 MW electric motor and an equally powerful 1 MW turboprop engine.

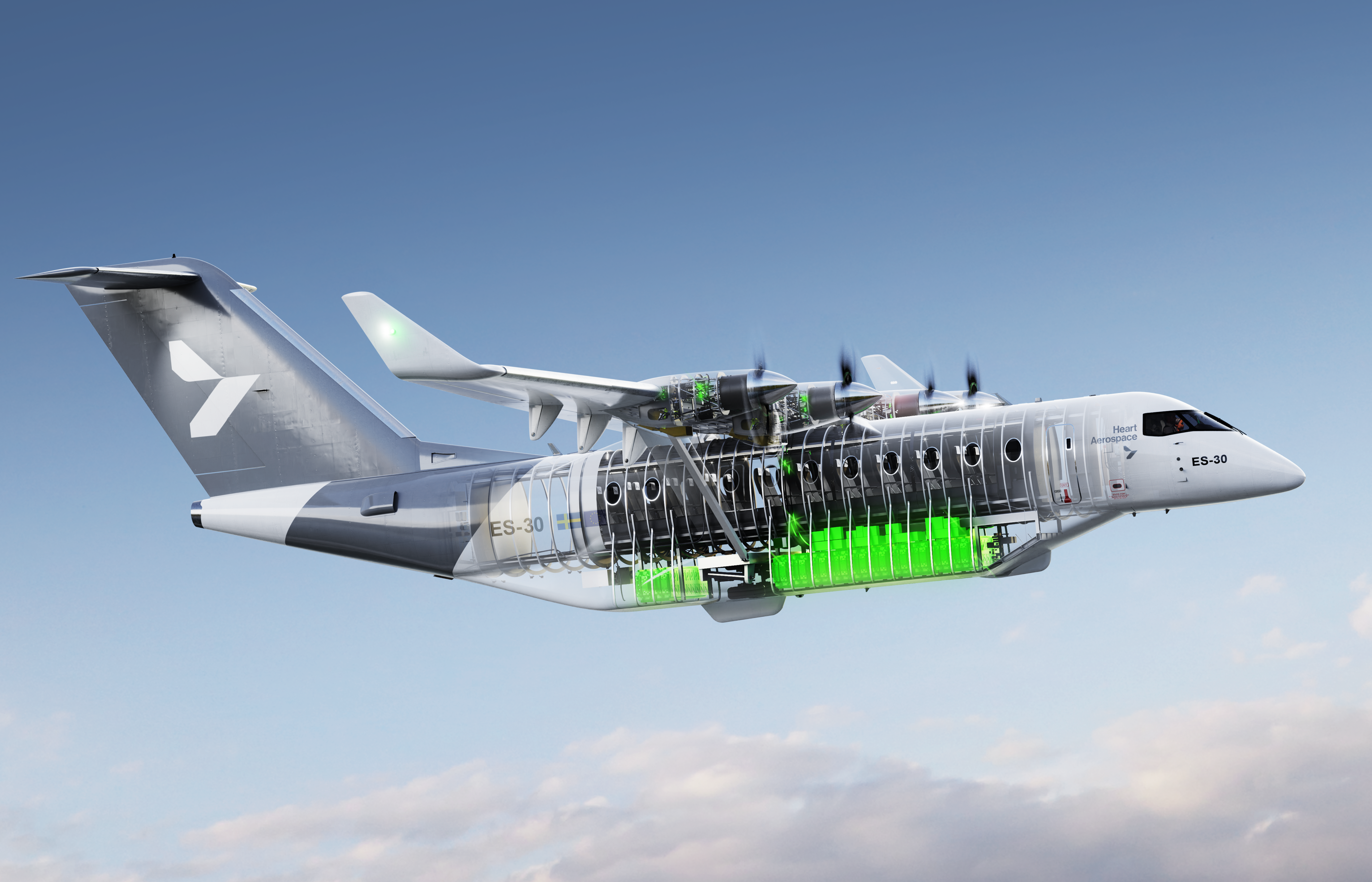

Swedish startup Heart Aerospace is developing a 30-seater hybrid electric aircraft. The company claims performance figures of 800 km of range in hybrid electric mode and a payload of 25 passengers, with an estimated EIS by 2028. [11]

To wrap it up

Hybrid electric propulsion poses itself as interesting technology in the support for the decarbonization of the aviation sector. The presence of a conventional engine (either reciprocating or gas generator) allows for greater ranges and payloads compared to fully electric aircraft, whilst still promising lower fuel burns and emissions. The propulsive architecture allows for great design flexibility, which allows to explore different aircraft concepts. Many companies have started to experiment with such technology, which shows encouraging interest with regards to hybrid electric propulsion in the aviation sector.

[1] European Commission, Directorate-General for Mobility and Transport, Directorate-General for Research and Innovation, Flightpath 2050 : Europe’s vision for aviation : maintaining global leadership and serving society’s needs, Publications Office, 2011, https://data.europa.eu/doi/10.2777/50266

[2] F. Gaspari et al. “D1.1: Concept of Modular Architecture for Hybrid Electric Propulsion of Aircraft”. In: Deliverable D1.1 of the MAHEPA Consortium (2017).

[3] C. E.D. Riboldi, “An optimal approach to the preliminary design of small hybrid-electric aircraft”, Aerospace Science and Technology (2018)

[4] C.E.D. Riboldi et al, “Predicting the effect of electric and hybrid-electric aviation on acoustic pollution”, Noise Mapping (2020)

[5] A. Sollazzo et al, “Acoustic Impact of Hybrid-Electric DEP Aircraft Configuration at Airport Level”. Applied Sciences (2021)

[8] https://www.skybrary.aero/aircraft/da36

[9] https://www.ampaire.com/vehicles/eco-caravan